Self-laminating labels are labels with a built-in clear protective layer that seals over the printed area to protect it from moisture, chemicals, abrasion, and fading. They provide a durable, long-lasting solution for labeling in harsh environments, making them a go-to option for industries that require permanent, legible identification.

For label distributors, offering self-laminating labels can be a game-changer. These labels are used in manufacturing, electrical work, healthcare, and safety compliance, where durability is critical. Understanding how they work and why businesses need them can help distributors increase sales and provide better solutions to their customers.

How Do Self-Laminating Labels Work?

Self-laminating labels have two main parts:

- The printed area – Where important information is written or printed.

- The clear laminate flap – A protective layer that folds over and seals the printed area, shielding it from damage.

Once applied, the laminate locks in the text or barcode, preventing smudging or fading from exposure to water, oil, chemicals, and rough handling.

Why Businesses Use Self-Laminating Labels

1. Long-Term Protection from Harsh Conditions

These labels are built to withstand tough environments, making them ideal for industries where standard labels would quickly wear out.

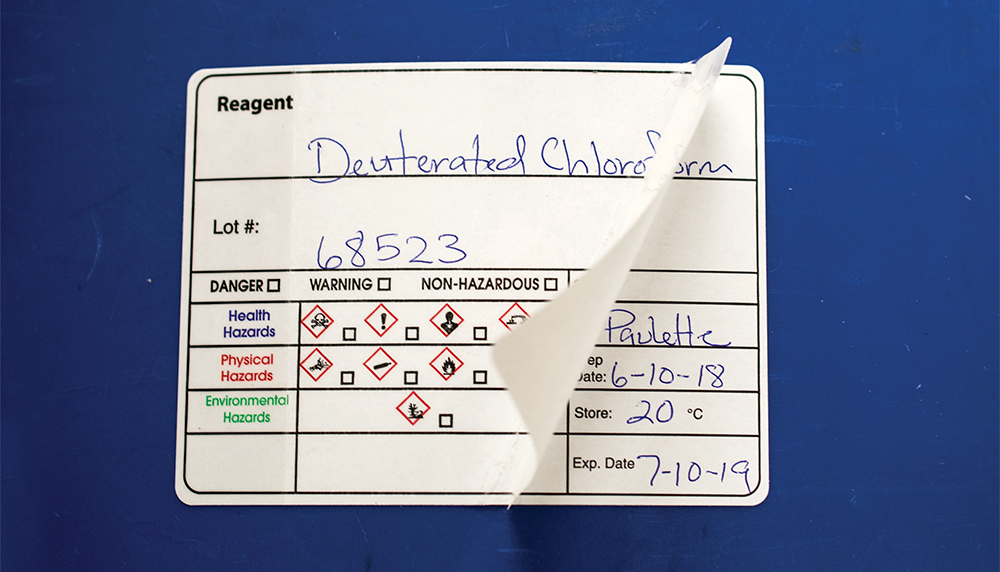

- Waterproof & Chemical-Resistant – Essential for laboratories, industrial equipment, and outdoor applications.

- Abrasion & Fade-Resistant – Ideal for machinery, safety labels, and compliance tags that need to last for years.

- Tamper-Proof – Once sealed, information cannot be altered without destroying the label.

2. Versatile Applications Across Industries

Distributors can sell self-laminating labels to a wide range of businesses, including:

- Electrical & Cable Labeling – Used by electricians and IT professionals to label wires and cables.

- Manufacturing & Warehousing – Equipment maintenance logs and safety labels.

- Healthcare & Medical Facilities – Medical charts, patient wristbands, and sterilization records.

- Outdoor & Industrial Use – Pipe marking, construction equipment labels, and chemical drum identification.

By offering custom self-laminating labels, distributors can help businesses reduce relabeling costs and improve compliance.

3. Easy Application for Instant Use

Businesses don’t need specialized equipment to use these labels—just print, write, or mark, then peel and seal. They can be applied to:

- Flat and curved surfaces

- Rough or uneven materials

- Heat-sensitive equipment where adhesive strength matters

For distributors, this ease of use makes them an attractive upsell to customers who need durable but simple labeling solutions.

How Distributors Can Market Self-Laminating Labels

1. Highlight Cost Savings & Durability

Businesses often replace labels due to fading, smudging, or peeling. Position self-laminating labels as a long-term investment that:

- Reduces the need for frequent relabeling

- Saves money on reprinting and replacement costs

- Improves compliance by keeping information legible

2. Offer Customization Options

Providing custom sizes, colors, and adhesives helps meet different industry needs. Some businesses may need:

- Color-coded labels for organizing assets

- Custom die-cut shapes for specific equipment

- Special adhesives for heat-resistant or extreme cold environments

The more custom options a distributor offers, the more businesses they can serve.

3. Show Real-World Use Cases

Customers are more likely to buy self-laminating labels when they see how other businesses benefit from them. Distributors can:

- Share case studies showing how these labels solved a problem (e.g., “A manufacturer reduced relabeling by 50% with self-laminating labels”).

- Provide sample packs so customers can test durability before placing bulk orders.

- Show comparison images of standard labels vs. laminated labels after long-term exposure to elements.

Why Distributors Choose Discount Labels for Self-Laminating Labels

Label distributors need a supplier they can rely on for quality, durability, and customization. Discount Labels provides:

- A variety of sizes and materials to fit any application

- Fast production times so distributors can fulfill customer orders quickly

- Custom printing options for bulk orders and specialized needs

- Durable, long-lasting adhesive solutions for challenging environments

Self-laminating labels are a must-have for businesses that need durable, long-lasting labeling solutions. If you’re a distributor looking for bulk pricing, fast turnaround, and customizable options, check out Discount Labels’ Self-Laminating Labels today.