Misprints cost more than just time—they can damage relationships and derail entire projects. But the good news? Many of these issues are avoidable. When distributors and production teams work together from the start, it’s easier to catch problems early and keep orders moving smoothly.

Prevent Misprints with These Steps

Distributors are the first line of defense when it comes to preventing misprints. These three practices can help you save time, reduce errors, and deliver exactly what your customer expects.

1. Ask the Right Questions

Before placing an order, take time to understand the label’s intended use. What is it being applied to? Does the customer have specific color matching needs? Is the label being hand applied or machine applied? These details can directly affect the material, adhesive, and design specifications needed for a successful label. The more context you gather, the fewer surprises you’ll run into later.

2. Be the Label Expert Your Clients Count On

Your clients rely on your guidance to make the right label decisions. Don’t be afraid to lead the conversation. Use our free resources like product literature, sales tools, and guidance to walk them through their options. Not sure what to recommend? Contact us before placing the order and let us know what your customer is asking for. We’ll help you understand the info you’ll need to gather for a smooth experience.

3. Get Sign-Off from All Decision-Makers

Before submitting an order, confirm that everyone on your customer’s side has reviewed and approved the final design. One overlooked typo or a missing logo can lead to costly reprints. A few extra minutes for a full team sign-off can save days of backtracking.

Feel Confident with Discount Labels

While you’re taking steps on your end, we’ve got your back on ours. Our team is committed to catching errors before they go to press—and helping you deliver great results every time.

1. We Review Files with a Prepress Checklist

Before anything goes into production, we start by checking the incoming files. That means reviewing:

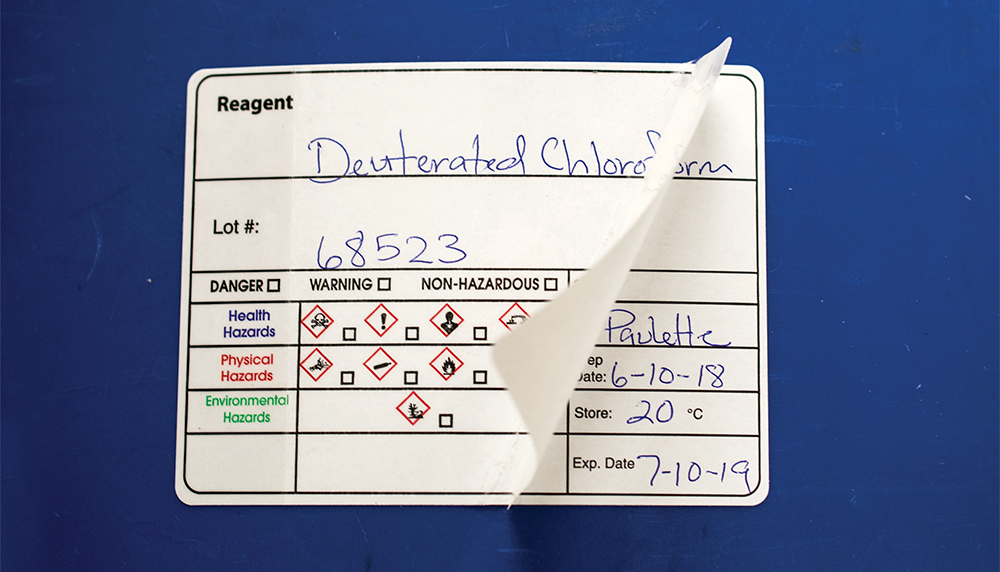

- Resolution and image quality

- Color profiles (CMYK vs RGB)

- Bleeds, margins, and cut lines

- Embedded fonts and linked graphics

If something doesn’t look right, we pause and reach out. This is where most misprints are caught—and avoided.

Why it matters:

Distributors often work with clients who aren’t print experts. Our team helps bridge the gap between what looks good on screen and what prints clean on paper, vinyl, or synthetic stock.

2. We Provide Digital Proofs and Ask the Right Questions

A digital proof is more than a preview—it’s a chance to double-check everything from spelling to layout before ink hits anything.

But just sending a proof isn’t enough. We make sure to ask:

- Does this layout reflect the client’s intent?

- Are key elements readable at size?

- Do design elements match the physical label dimensions?

We don’t wait for confusion—we try to head it off early. If something looks off, we flag it.

3. We Run Visual Checks During Press and After

Once printing begins, our operators know what to watch for. They perform regular checks for:

- Color shifts

- Image sharpness

- Material alignment

- Inconsistent coverage or streaking

Labels are also inspected post-press to catch any visual or finishing issues before packing.

Why this step matters:

Some errors aren’t digital—they show up in execution. A good process doesn’t stop once the proof is approved.

Ready to Send in Artwork? Let’s Make It Right the First Time.

Preventing misprints isn’t about being perfect—it’s about being prepared. With the right questions, clear approvals, and a reliable print partner, you can keep every order on track and every customer happy.

When you’re ready to submit artwork, head to our Art Help page for file setup tips and tools that make the process easier. And if something’s unclear, our team is always here to help.