Repositionable labels rely on specialized adhesives known as microsphere adhesives, enabling them to stick securely yet peel away cleanly multiple times without residue.

These adhesives use tiny, spherical particles to form a discontinuous bonding surface, ensuring easy removal and repeated application without damaging surfaces or leaving adhesive traces.

The Technology Behind Repositionable Adhesives

The unique properties of repositionable adhesive labels stem from advanced adhesive technologies, primarily microsphere and acrylic-based adhesives:

- Microsphere Adhesives: Tiny adhesive spheres minimize surface contact, creating low initial adhesion and easy removability, ideal for multiple repositioning.

- Acrylic-Based Adhesives: Offer durability and environmental resistance, maintaining adhesion over repeated uses without becoming permanent.

Industries Where Repositionable Labels Thrive

Distributors will find repositionable labels highly valuable across multiple sectors, enhancing their ability to meet diverse customer needs:

Retail and Promotions

- Temporary pricing labels

- Promotional stickers

- Product labels requiring regular updates

Warehousing and Logistics

- Easily movable inventory labels

- Flexible asset management

- Temporary bin labeling

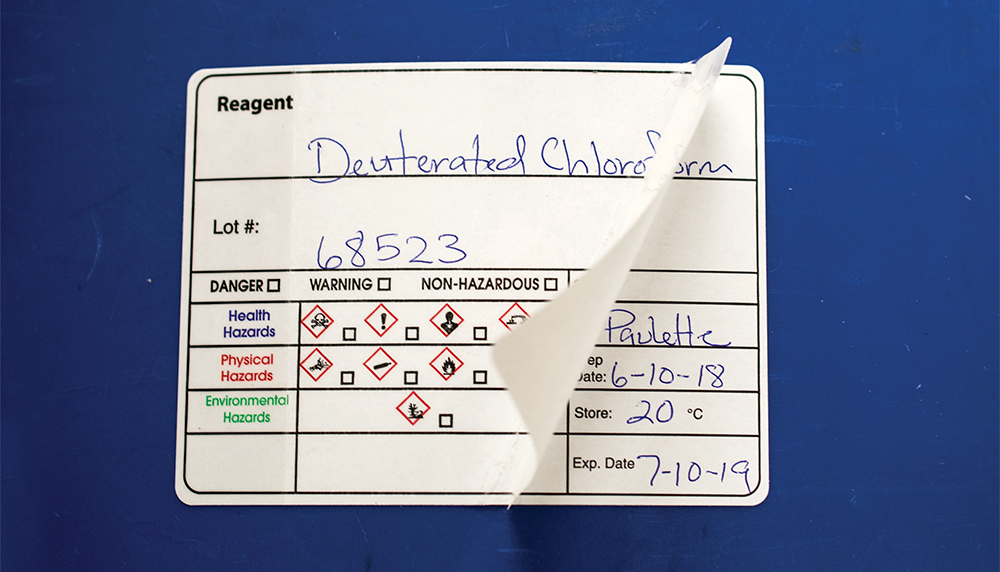

Pharmaceutical and Healthcare

- Removable patient labels

- Temporary medical equipment labeling

- Clean removability without residue

Food and Beverage

- Labels for reusable containers

- Easily updated date and ingredient labels

- Flexible promotional labels

Advantages for Distributors

Offering repositionable labels provides distributors with significant benefits:

- Versatility: Serve a broader customer base across various industries.

- Cost Efficiency: Customers reduce waste by reusing labels multiple times.

- Customer Loyalty: Reliable labeling solutions encourage repeat business.

Add Repositionable Labels to Your Offering

If you’re looking to expand your label solutions, repositionable labels offer significant value and versatility. Our selection of repositionable labels is specifically designed to meet the flexible needs of diverse industries, helping you enhance your offerings and keep your customers satisfied.

FAQs About Repositionable Labels

What surfaces are best suited for repositionable labels?

Repositionable labels perform best on smooth, non-porous surfaces such as glass, metal, and plastics. For rougher surfaces, it’s recommended to perform a test beforehand to ensure suitable adhesion.

How many times can repositionable labels be reused?

Typically, repositionable labels can be reused multiple times without losing adhesive quality. However, the exact number of reapplications varies depending on adhesive type, surface condition, and environmental factors.

Do repositionable labels leave any residue?

No, repositionable labels are specifically formulated to peel away cleanly without leaving any adhesive residue or damaging surfaces, even after multiple uses.

Can repositionable labels become permanent?

Most repositionable adhesives are designed to remain removable. However, some adhesives may gradually increase in bond strength over time, becoming semi-permanent. Choose adhesives carefully based on intended application.

Are repositionable labels customizable?

Yes, repositionable labels can be customized to suit specific needs in various shapes, sizes, and designs, accommodating diverse applications and industry requirements.